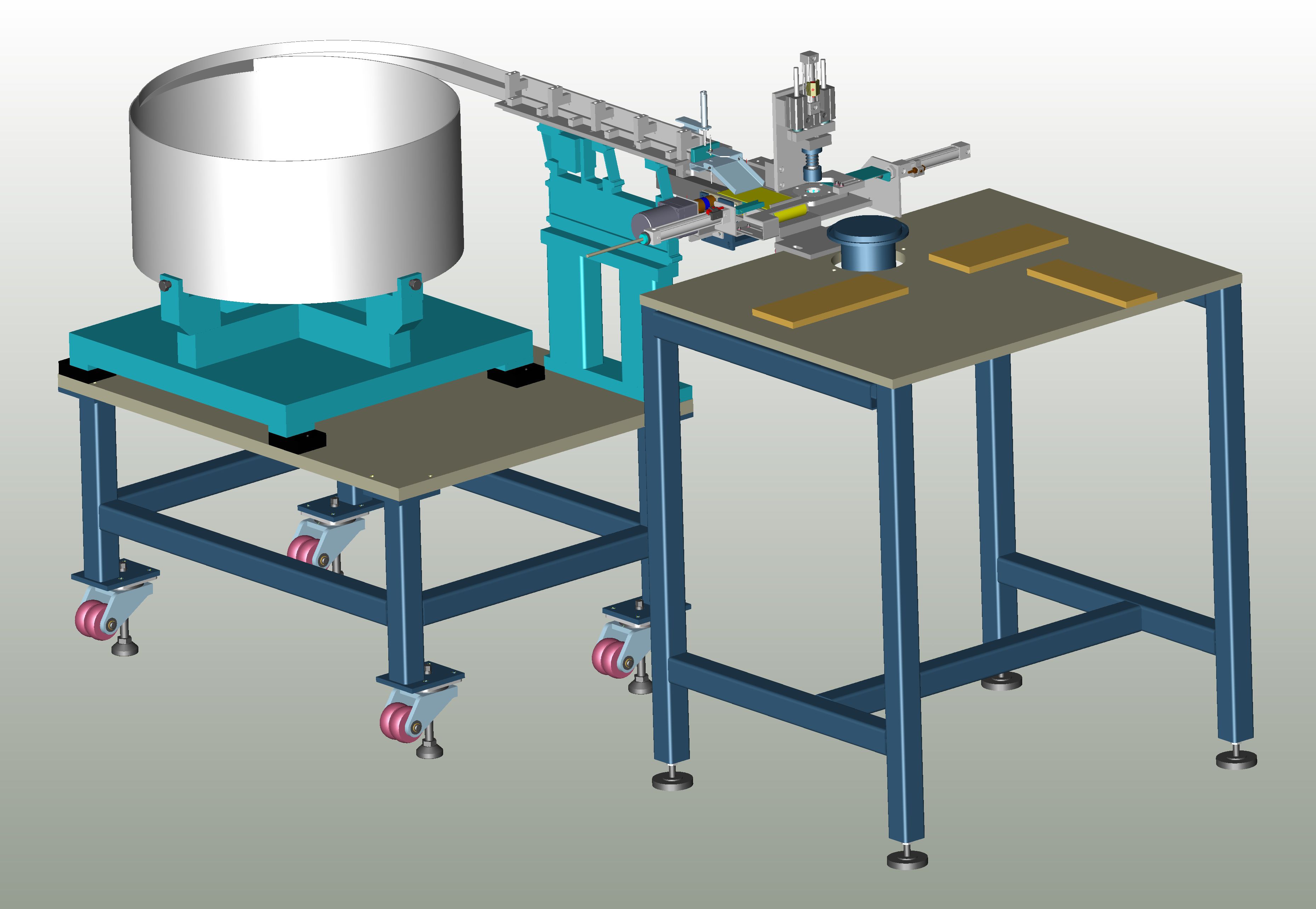

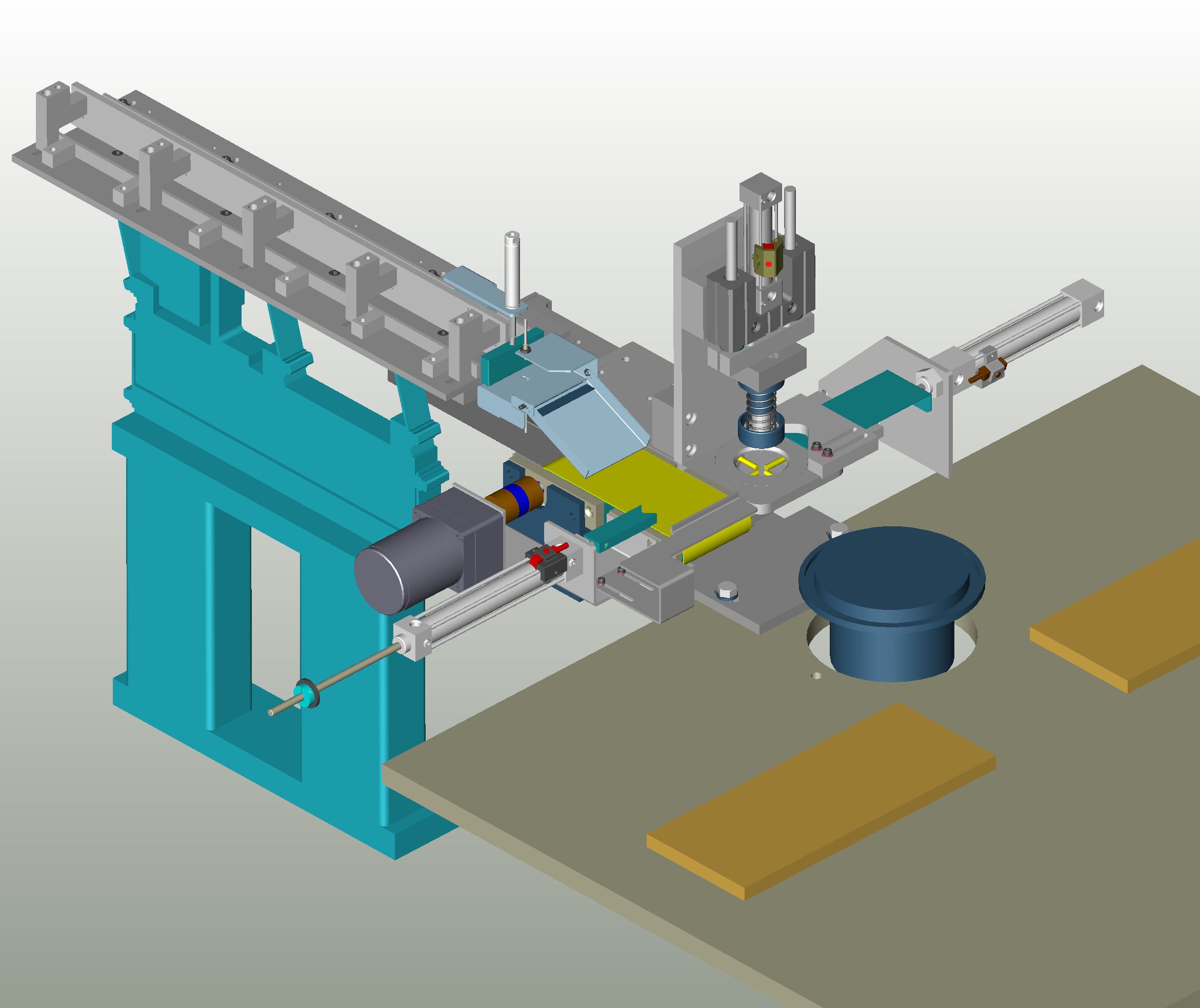

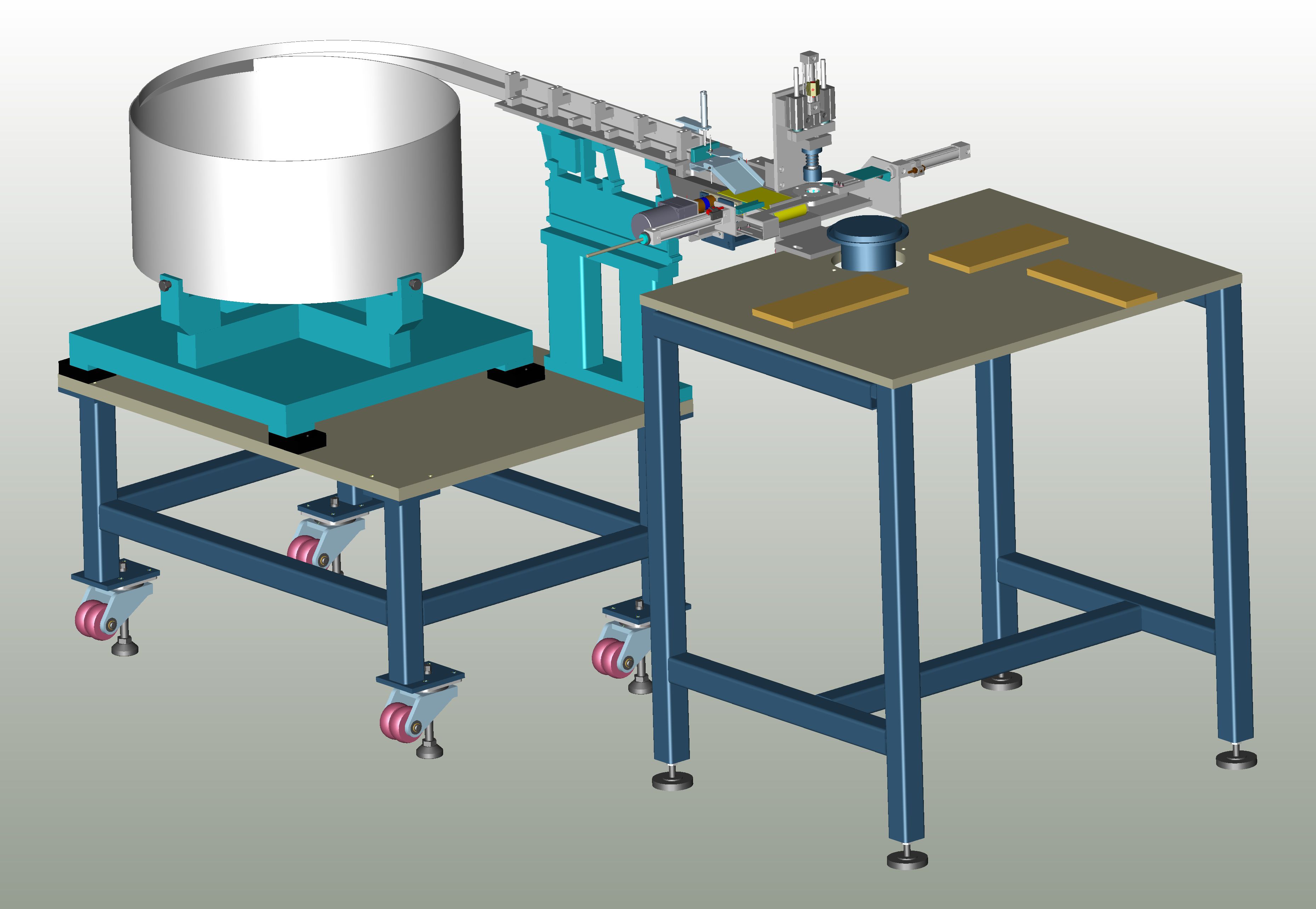

This machine was designed to transfer seals of different cross section and diameters from the bowl feeder to a preexisting piece of equipment where the seals are trimmed to their final size. The chuck spins at a constant speed during the entire operation. Seals are accurately placed on the chuck at a rate of 1 every 3.2 seconds (well within the 5 second requirement). In the image above, the table at the far right was preexisting, while the transfer mechanism (which is located between the bowl feeder and the preexisting piece of equipment) was designed by Evolution Engineering. The machine is operated over 120 hours per week. Seal trimming mechanisms are located in brown areas on table below but are not shown for proprietary reasons. This prototype seal transfer machine uses several newly innnovated systems in its operation and will be incorporated into future builds.